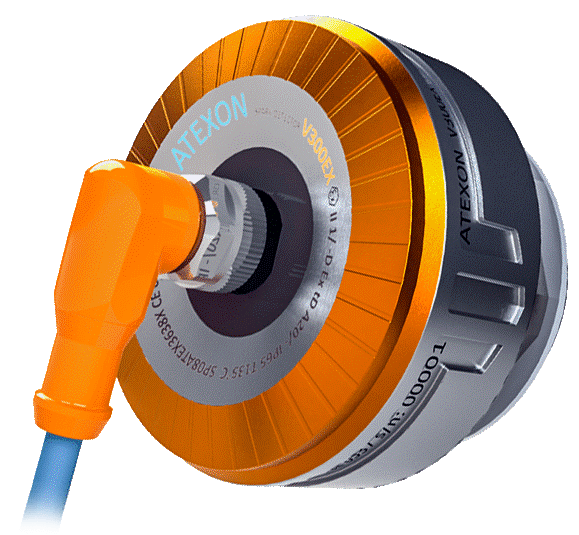

Atexon V300EX

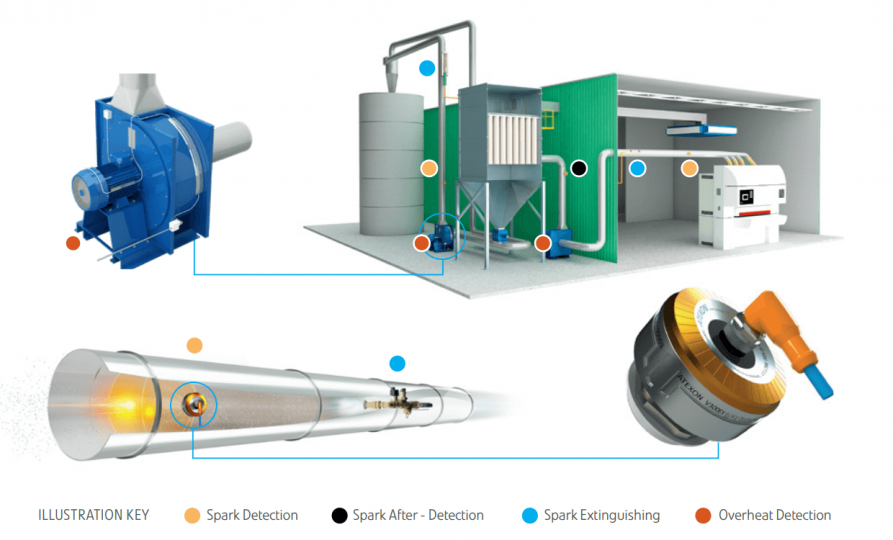

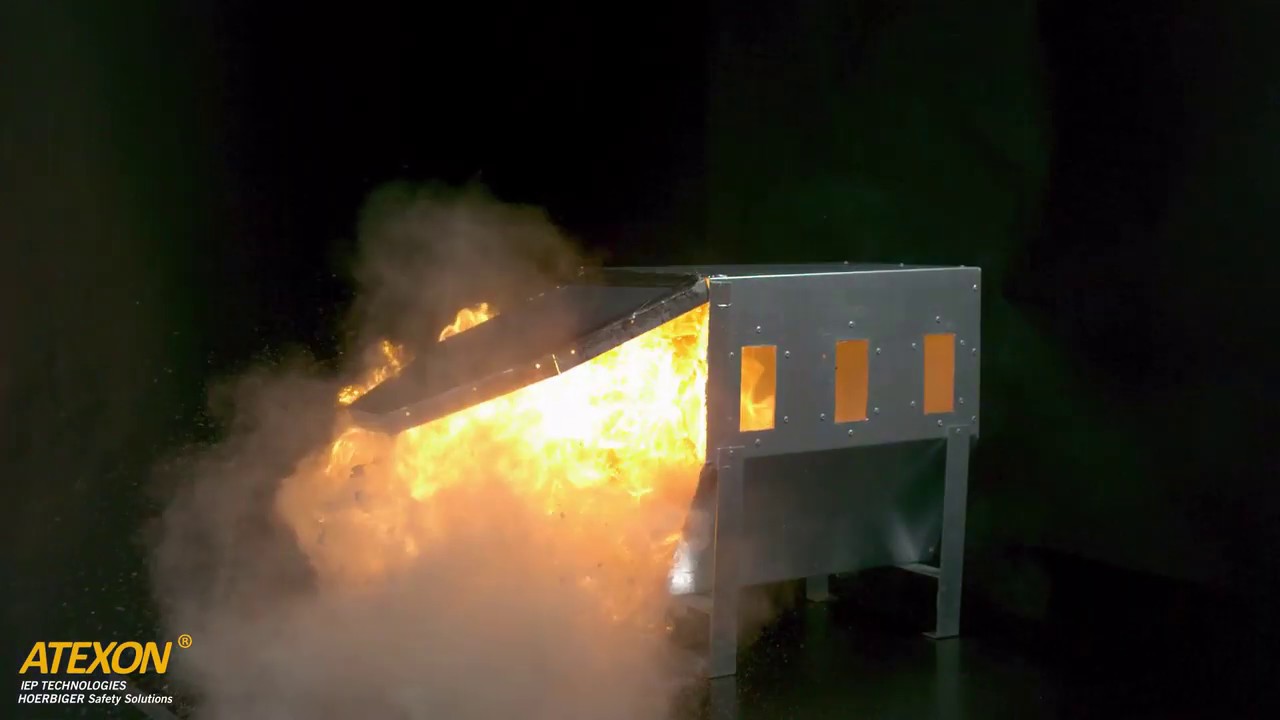

Dust collection systems are the archetypal application for spark detection protection. Explosive dust-air mixtures often form inside dust extraction systems.

Such mixtures can be ignited by sparks, embers, hot objects or static electricity. The patented V300EX spark detection family offers supreme detection technology for fast fire prevention. The extra wide field of view and detection spectrum and daylight filter make it possible to use the detector in a wider range of working conditions.

Properties:

- 180° field of view

- Detects light-emitting sparks

- Detects coal heat even under 300 °C

- Low and protected lens construction

- ATEX approved model for zone categories 20, 21 and 22

- Model VF300EX includes a daylight filter

Protecting Dust Collection Systems

Dust collection systems are the archetypal application for spark detection protection. Explosive dust-air mixtures often form inside dust extraction systems. Such mixtures can be ignited by sparks, embers, hot objects or static electricity.

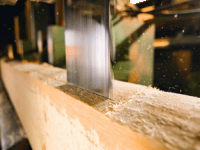

Usually these ignition sources are caused by a damaged blade, a wedged foreign object, resin collected on the fan blades or poor machine grounding. In the mechanical wood working industry, as many as half of all fires are caused by an overheated machine due to bearing failures or blocked ducts in the fan.

A dust explosion and burning material can advance into a dust silo or travel backwards through a return air duct into the production area. All dust collection system fires pose a grave danger to employees and usually cause a lengthy production outage. Large factory fires are also a concern for insurance companies, who indicate that filters, dust collection bins and silos are the areas at greatest risk.

Additional applications where Atexon® can provide protection include wood processing planers, sawmill trimmers, pellet pressing, crushers, and the conveyors and elevators found at ports that handle large volumes of material flow.

Unique Properties

Key Advantages

Decentralised, Bus-based system

(Atexon VR18Z Control Panel)

Provides extra safety level by redundant operation for each protection area

Efficient installation; control panel comes with 18 zones as standard, therefore no additional system costs with future expansion

Installation is less costly owing to reduced cabling and labour

Ease of use; no programming needed

Ease of maintenance; all critical parts are at the protection zone (decentralised)

Wide viewing angle/range of detection

(Patented 300EX model)

180˚viewing angle

Eliminates blind spots

Ideal for high material flow applications

Broad detection spectrum

(Patented 300EX model)

Detection of different ignition sources, including sparks and hot particles, i.e. detection of Visible, Infrared and Near Infrared

Superior detector design

Small and durable detector; vibration insensitive, housing made of stainless steel therefore less abrasion and greater protection of the lens window

Ease of installation; no welding necessary

Ease of maintenance; no tools needed

Superior water extinguishing system

Water flow monitoring, water temperature monitoring and ball valve monitoring

Fast, spring-loaded water nozzles

Fan overheat monitoring

(measures over 3-4 metres)

Eliminates other risk sources

More reliable than single point temperature measurement

Can be used for any other equipment

Stainless steel tanks

Long life

Lower product life time costs

High quality materials

Extremely low maintenance costs

Long product life time

Automatic system self-tests

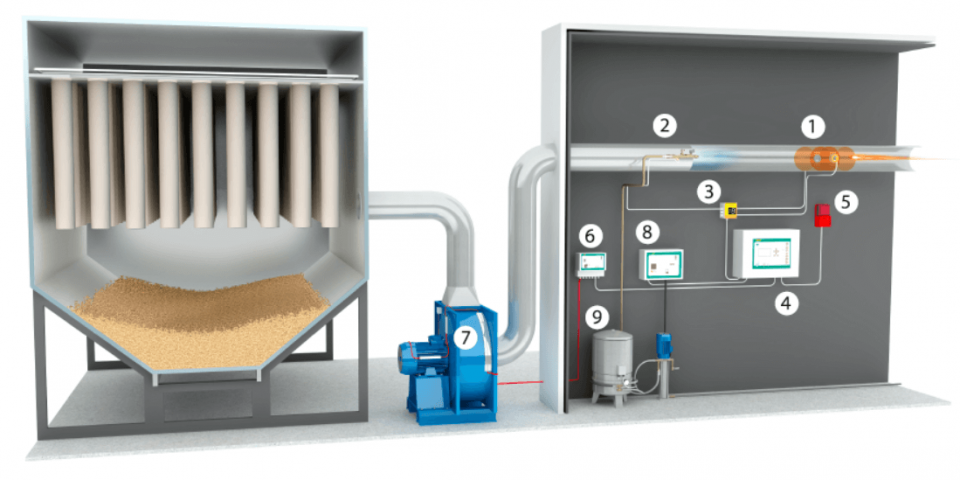

The System

Key Features

1) The spark detectors detect the ignition sources in a millisecond.

2) The extinguishing unit extinguishes sparks and embers with a small amount of water.

3) The signal router guides and monitors the extinguishing event.

4) The VR18Z control panel monitors the whole system.

5) The signal device gives alarms using a combined strobe/sounder.

6) The blower controller stops the blowers in case of overheating or a spark shower.

7) The overheat sensing cable monitors the blower bearings and the blower perimeter.

8) The pressure booster controller guides the water pump and the heat tracing cables.

9) The pressure booster ensures airless extinguishing water with correct pressure.

Atexon. The Spark Detection System

Market Segments

Wood Panel

MDF, OSB, Particle Board and Plywood.

Woodworking

Flooring, Furniture and Sawmills.

Metal

Manufacturing, Processing and Metalworking.

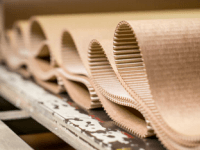

Pulp and Paper

Packaging, Paper and Pulp.

Tissue

Tissue Converting & Manufacturing and Air-laid.

Hygiene

Nappies, Incontinence and Sanitary Pads.

Recycling

Metal, Paper, Sludge Drying, Waste and Wood.

Bioenergy

Heat & Power Plants and Pellet Production.

Power Generation

Coal, Power Plants, Turbines and Wind Mills.

Food

Animal Feed, Food Processing, Cacao, Cereal, Coffee, Grain and Sugar.

Tobacco

Cigarettes, Cigarette Filters, Moist Snuff and Tobacco Dryers.

Port Facilities

Ports & Logistics Terminals.

Other Market Segments:

Chemicals / Oil Refineries / Pharmaceutical / Powder Coating / Printing / Rubber and Plastics / Textiles