Introduction to BESS.

Renewable Energy technologies such as solar and wind are at the mercy of the prevailing weather conditions, only able to operate intermittently, creating a problem of balancing supply and demand.

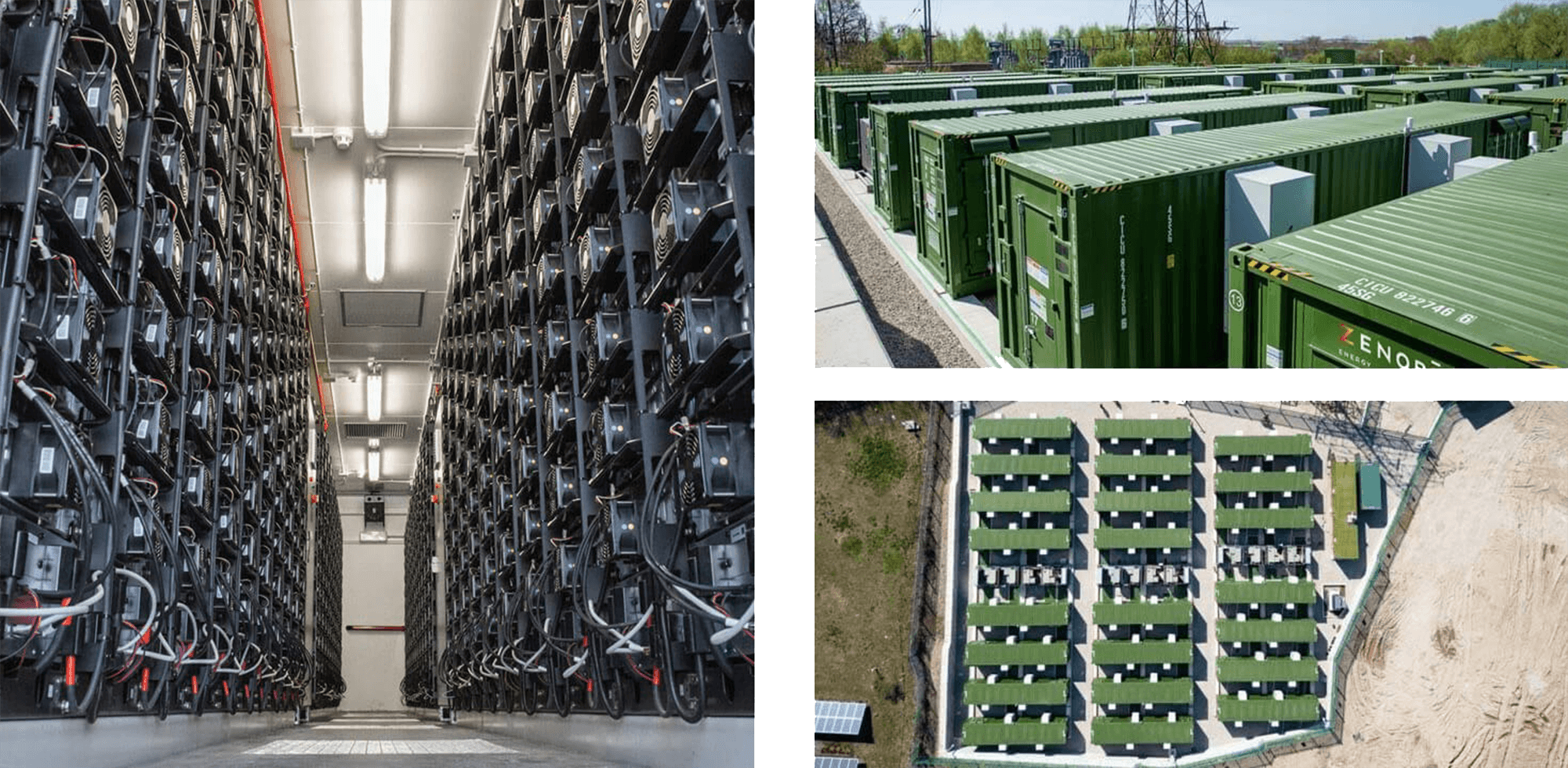

Solutions that have been developed in recent years are Battery Energy Storage Systems (BESS), having the ability to capture and store excess generated electricity for delayed discharging. A BESS can also be standalone, connected directly to the grid.

BESS as an industry is still very much in its infancy, however all forecasts point to exponential growth on a global scale. Nobel has been at the vanguard of this emerging sector, providing:

- Fire protection to a 41MW grid-scale in-building BESS in the West Midlands on behalf of leading BESS integrator, GE.

- Fire protection to containerised BESS units in the UK and mainland Europe.

- Consulting and maintenance work on behalf of BYD, the major Chinese lithium-ion battery manufacturer and BESS solutions provider operating in the UK

Regulations and Fire Testing

As recently as 2014, private safety standards firm Underwriter’s Laboratory (UL) published the first safety standards relating to energy storage; UL 9540.

UL is the underlying standard on which many international and national organisations base their regulations and fire codes. In addition, UL 9540A was drawn up in November 2017 to specifically address ‘Thermal Runaway Fire Propagation in Battery Energy Storage Systems’. Three further iterations of the standard have been published in the intervening period, demonstrating a rapidly evolving regulatory environment.

Furthermore, more recently the National Fire Protection Association of the US published its own standard for the ‘Installation of Stationary Energy Storage Systems’, NFPA 855, which specifically references UL 9540A. The International Fire Code (IFC) published its most robust ESS safety requirements in the most recent 2021 edition.

Lithium-ion Batteries-The Risks

By far the most dominant battery type installed in an energy storage system is lithium-ion, which brings with it particular fire risks. Think spontaneously exploding mobile phones and laptops on planes that have hit the headlines in recent years.

- Lithium-ion batteries are especially at risk of ‘thermal runaway’, a self-perpetuating chain reaction in which excessive heat keeps creating more heat, potentially spreading from one battery cell to the next and causing widespread damage.

- During thermal runaway, oxygen is believed to be self generated during cathode consumption, plus there are multiple internal sources of fuel in a lithium-ion battery (metals, plastic, electrical, flammable gases and liquids).

- Lithium-ion battery fires are ‘deep-seated’, as the materials involved in the ignition and propagation of the fire are tightly integrated into a cell, making fire-fighting a challenge.

- Lithium-ion battery fires are at risk of ‘re-flash’, hours or even days later having seemingly been put out.

- Lithium-ion batteries must be handled with care, in transport and during installation, as they are very sensitive to mechanical damage (such as crush or puncture) and electrical surges, which can result in short circuits leading to internal battery heating, battery explosions and fires.

- Battery management control systems can be faulty or fail, leading to an inability to monitor the operating environment, such as temperature or cell voltage, with the potential for overcharging.

Understanding Lithium-ion Battery Failure

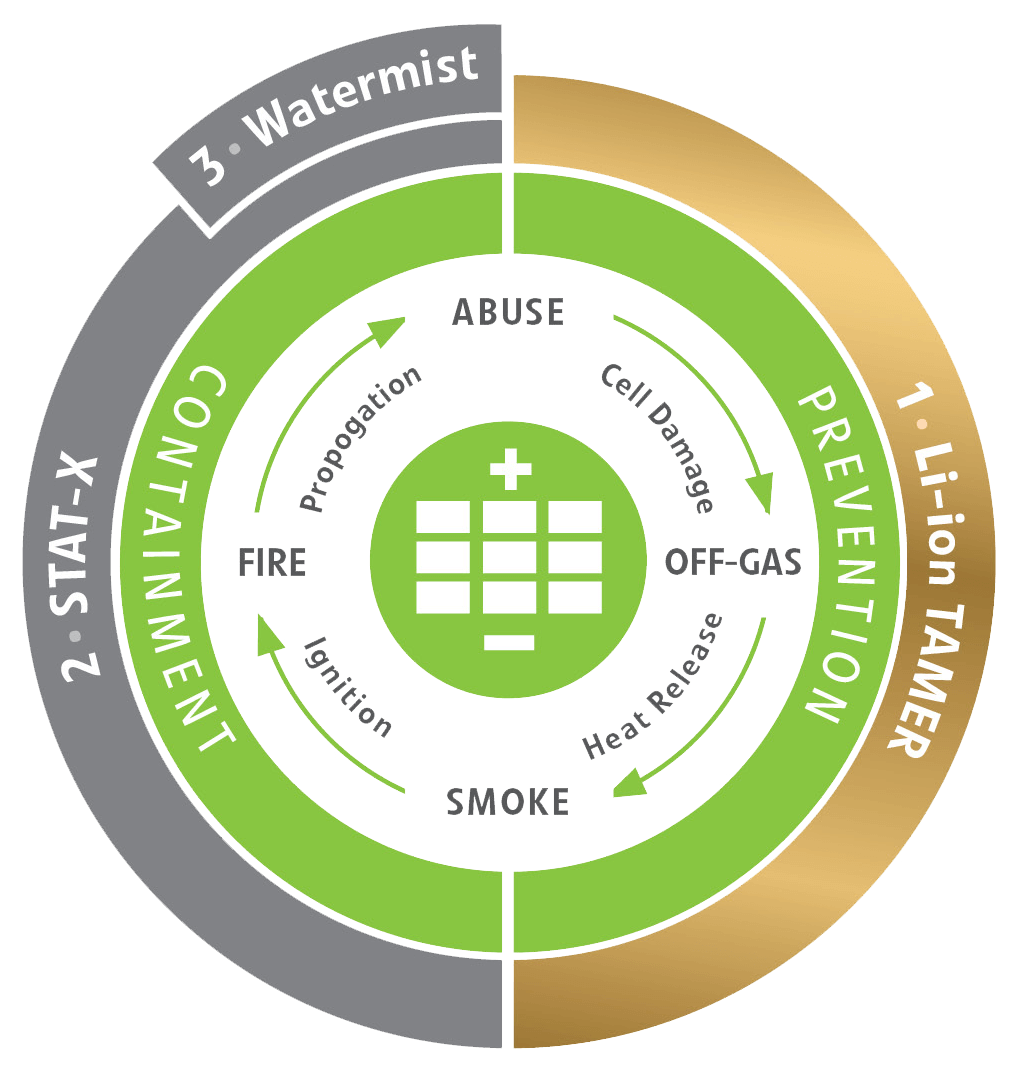

There are 4 main phases of lithium-ion battery failure:

- Battery Abuse

Cause of cell damage could be thermal, electrical or mechanical. - Off-Gas

Minute quantities of gas (e.g. hydrogen) and other cell vapours are generated, resulting in heat release. - Smoke

Catastrophic failure is imminent, level of heat likely to result in ignition and thermal runaway. - Fire

Likelihood of propagation dramatically increases.

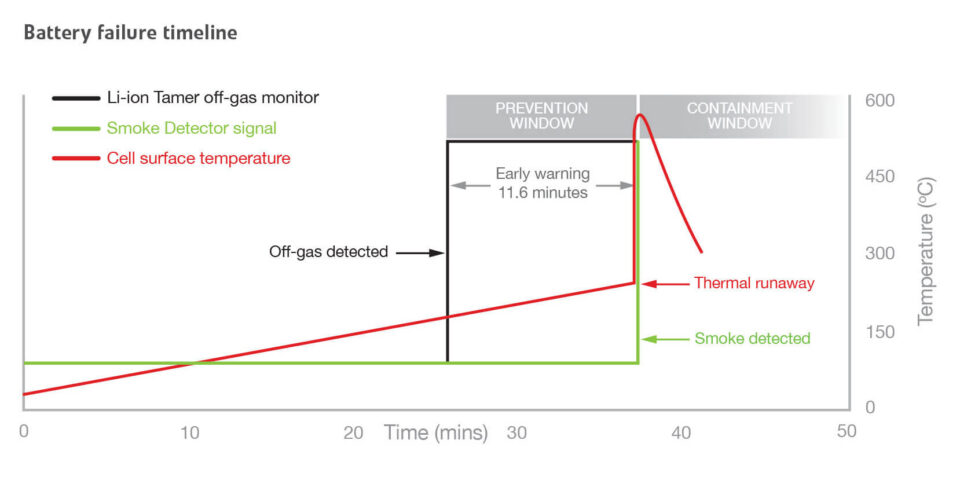

There are 2 main windows of opportunity to implement fire protection measures:

Off-gas generation in a lithium-ion battery should be considered as the critical window of opportunity to take action to Prevent thermal runaway or a fire condition in a BESS. Results from independent testing suggest an average of 11-12 minutes between detection of off-gas and thermal runaway / detection of smoke.

If preventative measures are unsuccessful and a damaged lithium-ion battery ignites, measures must be put in place to Contain the resulting fire and minimise the potential for propagation to other battery cells within the BESS.

Stage 1 Prevention / Li-ion Tamer GEN 3

Li-ion Tamer® GEN 3 is the leading battery risk prevention system designed to monitor Lithium-ion batteries of all chemistries, with a 5-second response time to detect any off-gases or toxic vapours in order to provide an early warning to BESS system providers.

The primary course of action is to send a signal to the Battery Management System to shut off power to batteries, with the aim of preventing any further increase in battery cell temperature, i.e. lower than the point of thermal runaway. Also ventilation activation to remove flammable gas accumulation, if required.

UL 9540A recognizes and quantifies off-gas events as pre-cursors to thermal runaway, while independent testing by DNV-GL has concluded that Li-ion Tamer® can prevent thermal runaway after a two-year battery failure testing program.

Many utility companies in the US and worldwide now mandate that Li-ion Tamer® must be installed as part of a BESS fire protection solution.

Li-ion Tamer® is a low-power and compact device, comprising a Controller, Off-Gas Monitoring Sensors and Reference Sensor.

Key Features:

- Early warning of lithium-ion battery failures

- Fast response time to off-gassing events

- Enable thermal runaway prevention with proper mitigation actions

- Single cell failure detection without electrical or mechanical contact of cells

- Calibration-free product

- Distributed sensing network provides localized gas detection

- Parts-per-million level detection threshold

- Long product lifetime

- Highly reliable output signal

- Low power consumption

- Compatible with all lithium-ion battery form factors and chemistries

- Easy installation

- Independent and redundant perspective on battery health

- Auto diagnostic capabilities

- Reduction/removal of false positive signals

- Several configurable communication protocols including digital outputs and serial communication

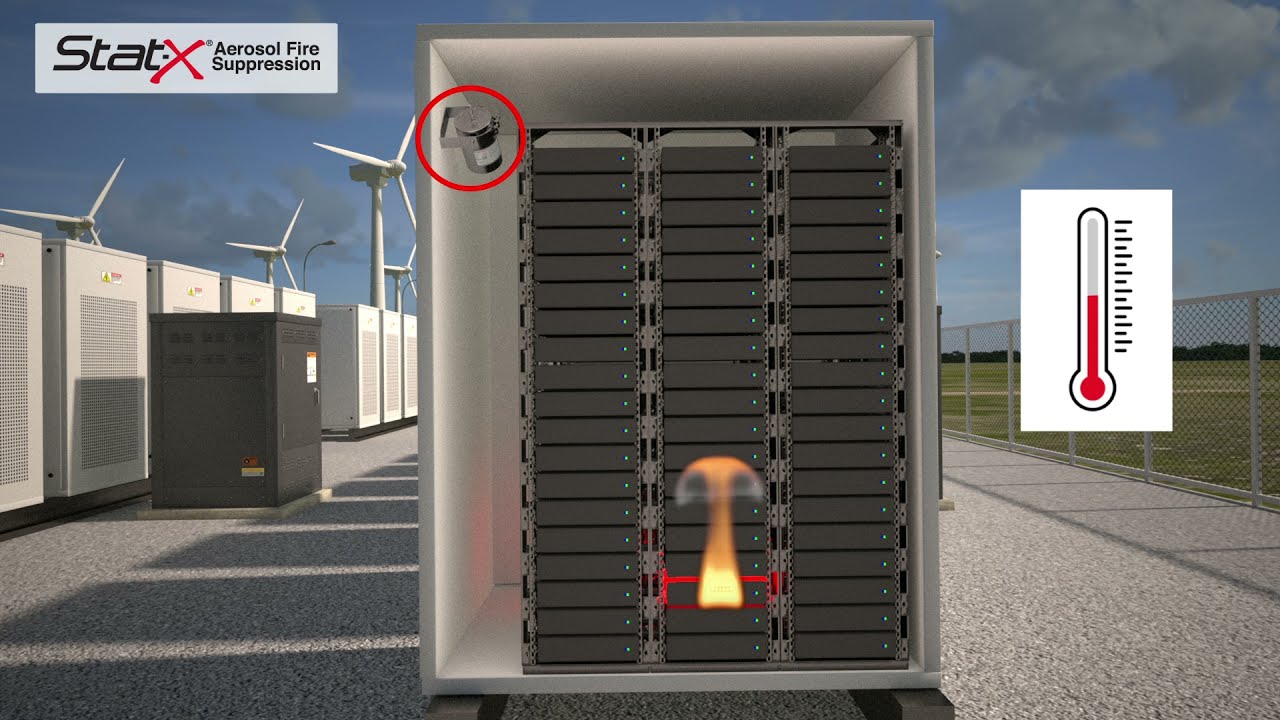

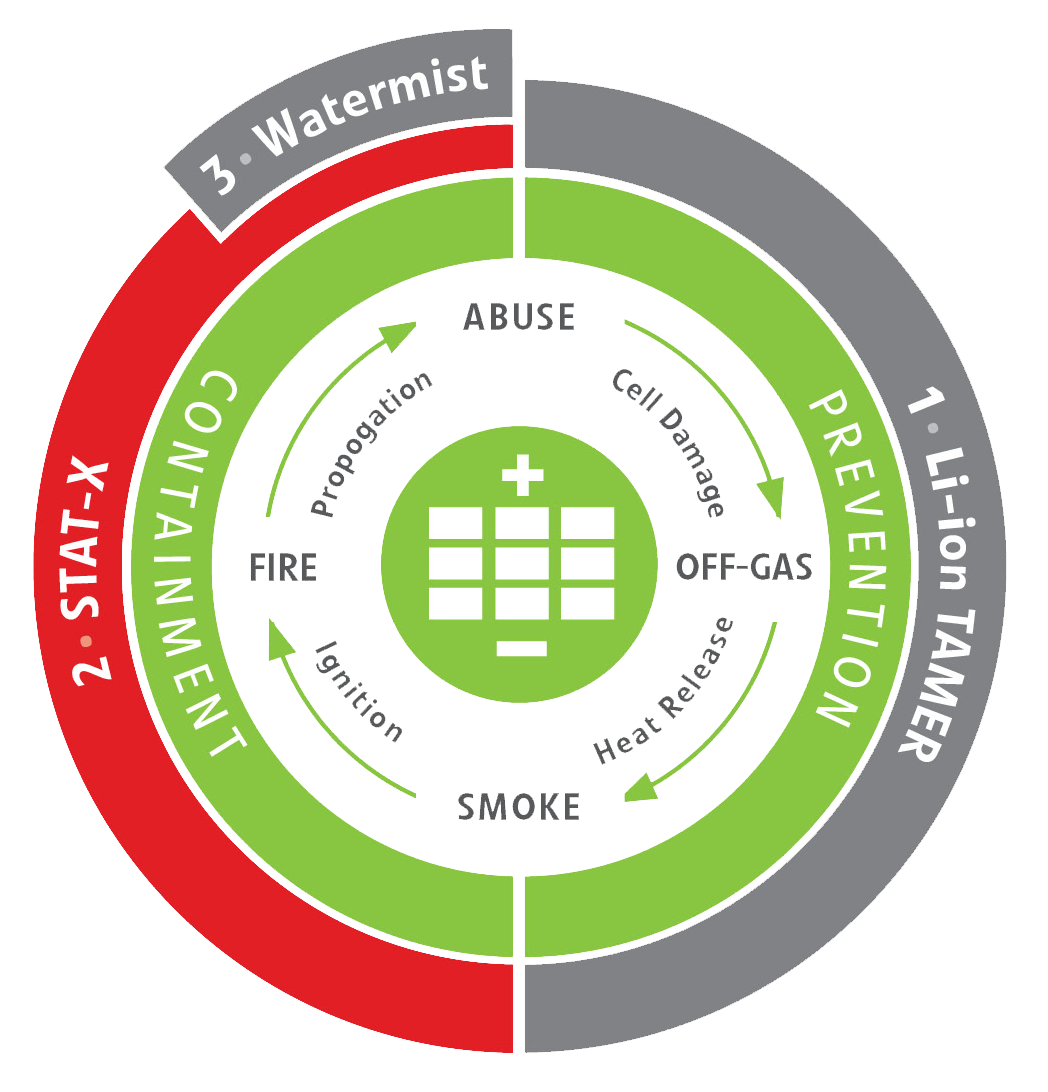

Stage 2 Containment / Stat-X

Stat-X® is the fire suppression system of choice of several lithium-ion battery OEMs and leading global BESS integrators, having undergone rigorous private and commercial testing in line with UL and NFPA standards.

In the event of off-gassing, there is no guarantee a BESS Battery Management System will shut down power to a battery in time or that a damaged battery cell(s) will not continue to increase in temperature to the point of thermal runaway. If so, Stage 2 of the Nobel fire protection solution must be deployed – Containment. Stat-X units automatically release ultra-fine particles and propellant inert gases, which effectively extinguish fires using less mass of agent than any other conventional extinguishing system.

DNV-GL testing has concluded that Stat-X® can put out a lithium-ion battery fire, that residual Stat-X® airborne aerosol in the hazard will provide additional extended protection against a re-flash of the fire, and that Stat-X® can reduce oxygen in an enclosed environment during a battery fire.

Stat-X® is an innovative, self-contained, environmentally friendly suppression system, proven to be extremely effective where there is a need to protect critical areas and high value enclosures.

Key Features

- Stat-X® is a condensed aerosol fire suppression system; it is compact and requires no pipework or nozzles with the generators being placed directly on or in the risk being protected.

- Stat-X® systems are bracket mounted within the BESS on the ceiling or walls, taking no valuable floor space.

- No cylinder weighing or hydro-static testing required.

- The potassium-based suppressant works in a similar way to gas but, unlike gas, the aerosol remains in suspension for up to an hour providing extended postfire security against re-ignition.

- Gas requires an airtight enclosure, which can only be ensured by passing a Room Integrity Test. Stat-X® has no such restrictions – calculations allow for un-closable openings.

- Stat-X® provides fast and secure knockdown of lithium ion battery fires, avoiding the associated damage to equipment and site of sprinklers or other water deluge systems.

- 10-year service life.

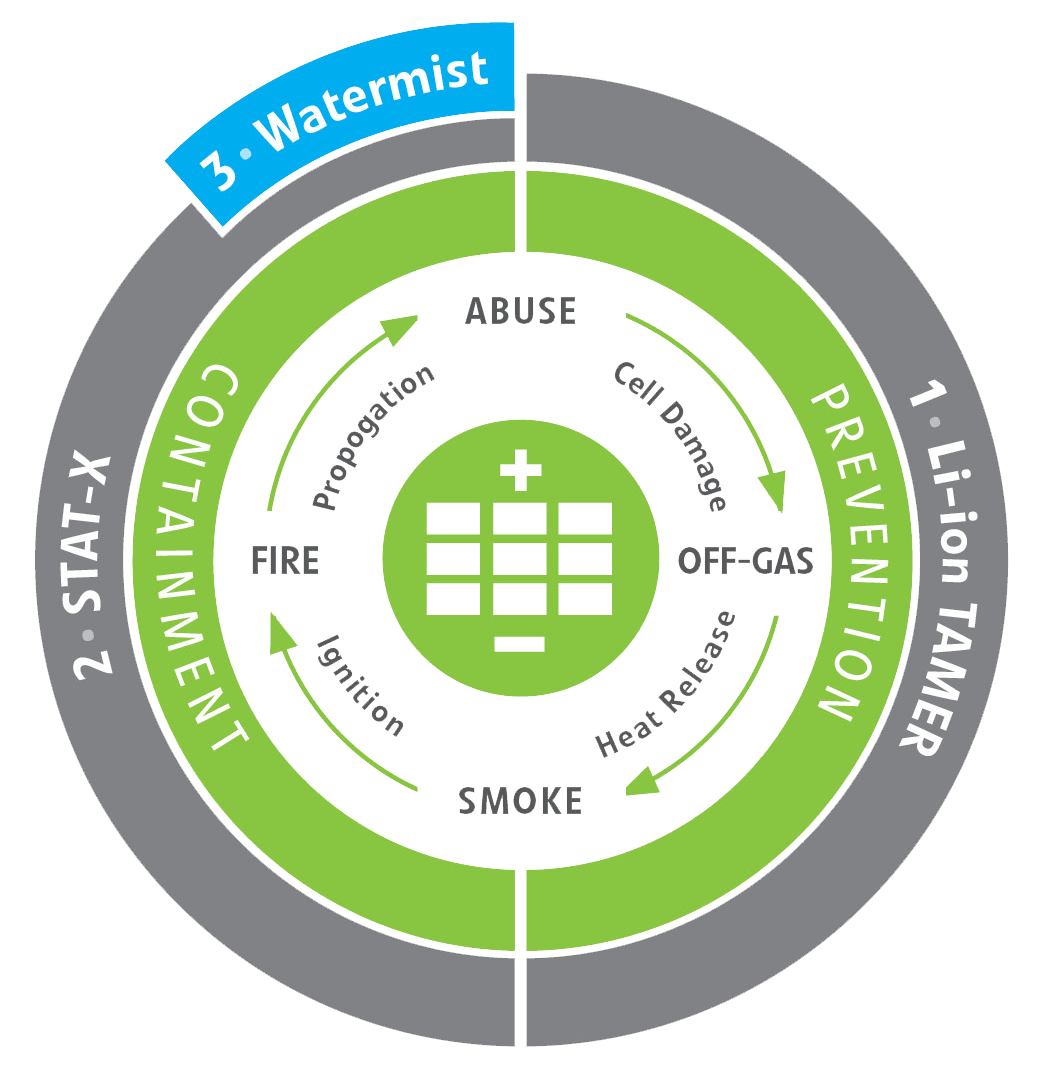

Stage 3 Cooling / Watermist

Nobel believes Li-ion Tamer® + Stat-X® represent best-in-class prevention and containment measures, together providing robust BESS fire protection.

However, the very nature of lithium-ion batteries means there is a certain element of randomness to how any given battery cell (or cells) reacts once damaged, be it the nature or extent of off-gassing, temperature increase, fire condition, or propagation from cell to cell.

There is also the potential for explosion if left unchecked. As previously mentioned, lithium-ion battery fires are at risk of ‘re-flash’, minutes, hours or even days later having seemingly been put out.

Nobel recommends a back-up Cooling option in the event of fire propagation, specifically a Watermist system with deluge misting nozzles located internally within the BESS. The system can be linked directly to a water supply such as a dedicated tank, alternatively a fire brigade pumping-in breech can be installed externally on the BESS container.

Conclusion

BESS assets can be found at all scales, from in-cabinet to container to in-building.

Although an energy asset, Battery Energy Storage Systems are not the preserve of traditional power and utility companies accustomed to dealing with the specialised operational demands. BESS developers and end use customers are as likely to be financial investors, property developers, industrial parks, factories or councils with limited understanding of the inherent risks and dangers.

Furthermore, as a relatively nascent industry, many firefighters and other emergency services have little or no experience of this type of hazard, which presents risk of fire, electricity and fume toxicity, with the use of water potentially perpetuating the battery fire by additional cell shorting. It goes without saying that water damage results in the total loss of asset, which at scale have a capital cost in the millions with attendant insurance issues.

As such, it is critical to work with BESS owners, contractors and integrators at the initial design stage to fully understand all aspects of fire risk and associated hazards specific to the site.

Li-ion Tamer® and Stat-X® are the principal lines of defence against a Lithium-ion BESS fire, however, there is a suite of additional solutions to consider in monitoring, protecting and managing fire risk:

- Control Panel technology

- Detection (Heat, Smoke, Gas, etc)

- Ventilation control

- Battery Separation and Containment

- Interface with customer house alarm and other systems

- Emergency procedures, including warning signs, sounders and manual release facility

- Communication with local fire brigades and other community stakeholders

- Maintenance, servicing and ongoing customer support

- Installation protocol – all BESS fire protection installations carried out by dedicated team of experienced Nobel engineers