Key Features of the Li-ion Tamer GEN 3 System:

- Early detection and prevention of lithium-ion battery failures, mitigating the risk of thermal runaway.

- Non-intrusive detection of battery cell failures, eliminating the need for mechanical or electrical contact with the cells.

- Independent and redundant perspective on battery safety, enhancing overall system reliability.

- Compatibility with various lithium-ion battery form factors and chemistries.

- Temperature and humidity monitoring at each sensing node, enabling precise environmental control.

- Scalable deployment options to protect battery storage systems of different sizes, ensuring cost-effective solutions.

- Easy installation and system configuration through user-friendly interface software, minimizing setup expenses.

- Calibration-free sensors and extended product lifetime, reducing the overall cost of ownership.

- Communication protocols, including relays and Modbus outputs, for seamless integration with existing systems.

Off-gas detection keeps BESSs running more safely, helping operators stay on top of potential risks and operational concerns. It gives early detection designed to identify and alert when a battery off-gases so users can take appropriate preventative safety steps to reduce or even avoid the effects of thermal runaway. This allows power to continue to be delivered when it is needed.

Key Aspects of Li-ion Tamer GEN 3 System

The Li-ion Tamer GEN 3 device detects the venting of battery electrolyte solvent vapors (off-gassing phase) that occur early in the failure mode of lithium-ion batteries.

Early detection of battery electrolyte vapours allows for proper mitigation steps to be taken to avoid a catastrophic thermal runaway failure.

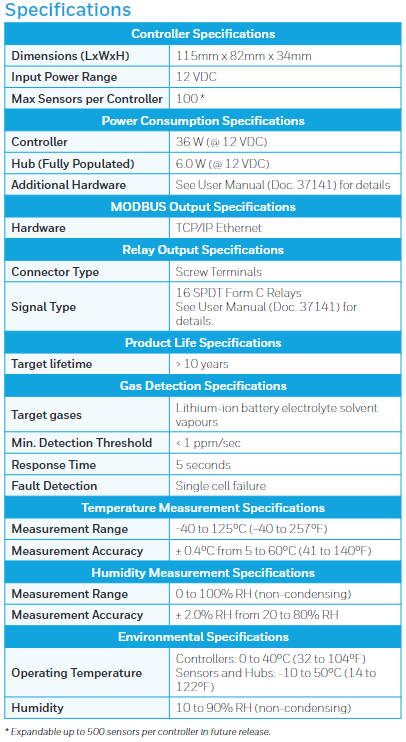

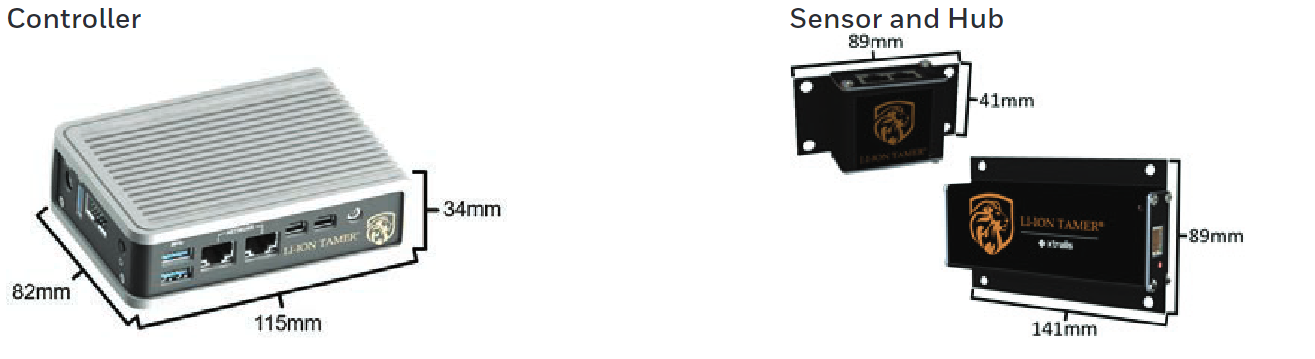

The Li-ion Tamer GEN 3 system consists of several components, including sensors, a hub, a power switch, a network switch, and a controller.

The sensing nodes in the Li-ion Tamer GEN 3 system include off-gas sensors with advanced algorithms for detecting battery electrolyte vapors. They do not require calibration, are compatible with all lithium-ion battery form factors and chemistries, and have a lifetime comparable to a typical lithium-ion battery system. The sensing nodes also include temperature and humidity sensors for environmental monitoring.

The sensing nodes are networked by the hubs and switches to the controller, which serves as the central point for managing and monitoring the entire system.

The controller of the Li-ion Tamer GEN 3 system has relays and Modbus TCP/IP outputs that can connect to the Battery Management System (BMS) or other control systems.

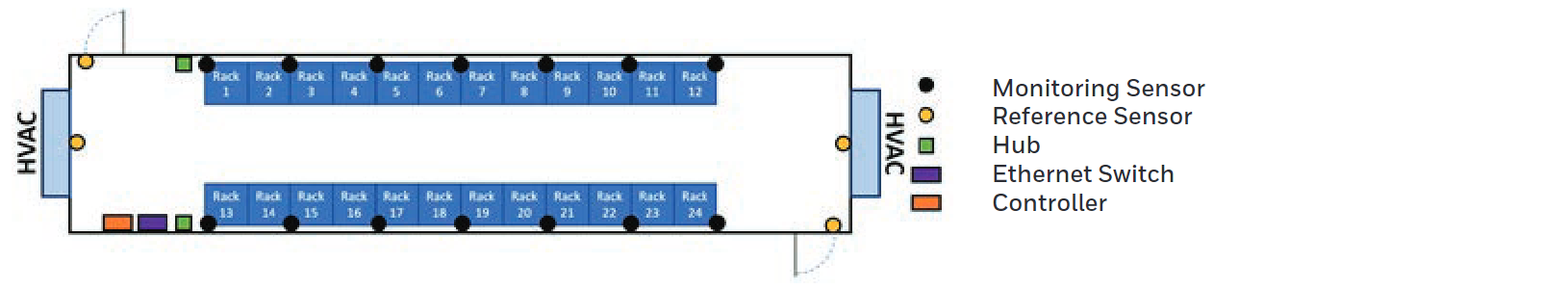

The system configuration of the Li-ion Tamer GEN 3 system typically includes monitoring sensors installed at the battery racks to monitor off-gas events, reference sensors to monitor the ambient environment and air inlets, hubs installed in respective sensor zones, and a controller and Ethernet switch for aggregating sensor signals. Optional Power over Ethernet (PoE) switches can also be used for distributing power to the system.

The Li-ion Tamer GEN 3 system requires minimal operation and maintenance procedures as the sensors are calibration-free and have a comparable lifetime to that of the Energy Storage System (ESS) battery system. The response of the gas sensors can be easily verified with a simple test. Activation of the sensors can be done using a supplied bottle of battery off-gassing compounds (Diethyl Carbonate, DEC) provided by Xtralis.

It is important to note that the Li-ion Tamer GEN 3 device detects the venting of electrolyte vapors from lithium-ion batteries but does not prevent fires or thermal runaway. It is not a standalone safety device and should be incorporated into a proper safety system. If the device responds, there is a risk of a battery fault that could lead to thermal runaway, and immediate evacuation from the area is advised to avoid injury.

- Early warning of lithium-ion battery failures – enable thermal runaway prevention with proper mitigating actions

- Single cell failure detection without mechanical or electrical contact to the cells

- Scalable deployment for cost effective protection of a wide range of battery storage systems

- Temperature and humidity monitoring at each sensing node

- Extended product lifetime

- Calibration-free product with highly reliable output signal

- Compatible with all lithium-ion battery form factors and chemistries

- Easy installation

- Independent and redundant perspective on battery health

- Auto diagnostic capabilities

- Reduction/removal of false positive signals

- Communication protocols including relays and Modbus serial

Applications: Not Just for BESS…

The versatile Li-ion Tamer GEN 3 device finds applications across various industries and settings. From stationary battery energy storage to automotive environments, data centers, manufacturing facilities, laboratory safety, and even shipping and storage, this cutting-edge device offers comprehensive solutions for enhanced safety and monitoring. Whether it’s protecting battery systems in data centers, ensuring safety during battery abuse testing, or maintaining secure storage of post-manufacturing batteries, the Li-ion Tamer GEN 3 device is a reliable choice for a wide range of applications.

Automotive

Car parks / garages

Charging bays

Vehicle test facilities

Laboratory Safety

Environmental chambers

Battery abuse testing

Stationary Battery Energy Storage

Containerized / modular systems

Built environment systems

Gigafactories / Manufacturing

Assembly lines

Battery formation process

Cell aging and EOL testing

Module or pack assembly

Shipping and Storage

Post-manufacturing storage

Battery-powered equipment

Data Centers

Battery UPS